While the linear elastic model for anisotropic materials is based on the fourth order elastic stiffness tensor C the linear elastic model for isotropic models is most often developed in terms of the elastic moduli shear, bulk, Youngs modulus and the Poisson ratio.

The single crystal stiffness tensor

Lets start our discussion with a single crystal stiffness tensor of Albite.

% density (g/cm3)

rho= 2.6230;

%

% crystal symmetry & frame

cs = crystalSymmetry('-1', [8.290 12.966 7.151], [91.18 116.31 90.14]*degree,...

'x||a*','y||b', 'mineral','An0 Albite 2016');

% the stiffness tensor C in (GPa)

C = stiffnessTensor(...

[[ 68.30 32.20 30.40 4.90 -2.30 -0.90];...

[ 32.20 184.30 5.00 -4.40 -7.70 -6.40];...

[ 30.40 5.00 180.00 -9.20 7.50 -9.40];...

[ 4.90 -4.40 -9.20 25.00 -2.40 -7.20];...

[ -2.30 -7.70 7.50 -2.40 26.90 0.60];...

[ -0.90 -6.40 -9.40 -7.20 0.60 33.60]],...

cs,'density',rho)C = stiffnessTensor (An0 Albite 2016)

density: 2.623

unit : GPa

rank : 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

68.3 32.2 30.4 4.9 -2.3 -0.9

32.2 184.3 5 -4.4 -7.7 -6.4

30.4 5 180 -9.2 7.5 -9.4

4.9 -4.4 -9.2 25 -2.4 -7.2

-2.3 -7.7 7.5 -2.4 26.9 0.6

-0.9 -6.4 -9.4 -7.2 0.6 33.6The effective isotropic stiffness tensor

An isotropic Albite material we assume here to consist of randomly oriented grains forming an uniform (isotropic) texture. In this case the Voigt and Reuss averages provide upper and lower bounds for the elastic properties of the material.

[C_iso_Voigt,C_iso_Reuss,C_iso_Hill] = mean(C,uniformODF(C.CS))C_iso_Voigt = stiffnessTensor (y↑→x)

density: 2.623

unit : GPa

rank : 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

118.33 35.47 35.47 0 0 0

35.47 118.33 35.47 0 0 0

35.47 35.47 118.33 0 0 0

0 0 0 41.43 0 0

0 0 0 0 41.43 0

0 0 0 0 0 41.43

C_iso_Reuss = stiffnessTensor (y↑→x)

density: 2.623

unit : GPa

rank : 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

93.83 34.16 34.16 0 0 0

34.16 93.83 34.16 0 0 0

34.16 34.16 93.83 0 0 0

0 0 0 29.84 0 0

0 0 0 0 29.84 0

0 0 0 0 0 29.84

C_iso_Hill = stiffnessTensor (y↑→x)

density: 2.623

unit : GPa

rank : 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

106.08 34.81 34.81 0 0 0

34.81 106.08 34.81 0 0 0

34.81 34.81 106.08 0 0 0

0 0 0 35.63 0 0

0 0 0 0 35.63 0

0 0 0 0 0 35.63The elastic moduli

The actual elastic properties of the material depend on the geometric microstructure and can not be computed without additional knowledge.

Based on the Voigt effective stiffness tensor we may now compute upper, directional independent bounds for all elastic moduli:

G = C_iso_Voigt.shearModulus

K = C_iso_Voigt.bulkModulus

E = C_iso_Voigt.YoungsModulus(xvector)

nu = C_iso_Voigt.PoissonRatioG =

41.4333

K =

63.0889

E =

101.9759

nu =

0.2306From the elastic moduli to the elastic tensors

Furthermore, any two of them entirely describe the linear elastic behavior of the material. In particular, we may recover the isotropic stiffness tensor from the bulk and shear moduli alone:

% the matrix entries

C11 = K+(4/3)*G ; C12=C11-2*G; C44=(C11-C12)/2;

% this gives exactly the effective Voigt stiffness tensor as computed above

stiffnessTensor(...

[[ C11 C12 C12 0.0 0.0 0.0];...

[ C12 C11 C12 0.0 0.0 0.0];...

[ C12 C12 C11 0.0 0.0 0.0];...

[ 0.0 0.0 0.0 C44 0.0 0.0];...

[ 0.0 0.0 0.0 0.0 C44 0.0];...

[ 0.0 0.0 0.0 0.0 0.0 C44]],cs)ans = stiffnessTensor (An0 Albite 2016)

unit: GPa

rank: 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

118.33 35.47 35.47 0 0 0

35.47 118.33 35.47 0 0 0

35.47 35.47 118.33 0 0 0

0 0 0 41.43 0 0

0 0 0 0 41.43 0

0 0 0 0 0 41.43or from the Youngs modulus and the Poisson ratio

S11 = (1/E); S12 = (-nu/E); S44 = 2*(S11-S12);

inv(complianceTensor(...

[[ S11 S12 S12 0.0 0.0 0.0];...

[ S12 S11 S12 0.0 0.0 0.0];...

[ S12 S12 S11 0.0 0.0 0.0];...

[ 0.0 0.0 0.0 S44 0.0 0.0];...

[ 0.0 0.0 0.0 0.0 S44 0.0];...

[ 0.0 0.0 0.0 0.0 0.0 S44]],cs))ans = stiffnessTensor (An0 Albite 2016)

unit: GPa

rank: 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

118.33 35.47 35.47 0 0 0

35.47 118.33 35.47 0 0 0

35.47 35.47 118.33 0 0 0

0 0 0 41.43 0 0

0 0 0 0 41.43 0

0 0 0 0 0 41.43Formulas between the elastic moduli

As a consequence, Young's modulus and the Poisson ratio can be computed directly from the bulk and shear modulus (and vice versa)

% formulae for the Poisson ratio

(E/G-2)/2

(3*K-E)/(6*K)

% formulae for the Young's modulus

2*G*(1+nu)

3*K*(1-2*nu)ans =

0.2306

ans =

0.2306

ans =

101.9759

ans =

101.9759Lame constants

The second way to represent the elastic behavior of an isotropic medium is by means of the Lame constants

lambda = nu/(1-2*nu) /(1+nu) * E;

mu = G;In terms of the Lame constants the stiffness tensor is given by

2 * mu * stiffnessTensor.eye(cs) + lambda * dyad(tensor.eye,tensor.eye)ans = stiffnessTensor (An0 Albite 2016)

unit: GPa

rank: 4 (3 x 3 x 3 x 3)

tensor in Voigt matrix representation:

118.33 35.47 35.47 0 0 0

35.47 118.33 35.47 0 0 0

35.47 35.47 118.33 0 0 0

0 0 0 41.43 0 0

0 0 0 0 41.43 0

0 0 0 0 0 41.43and we may directly formulate Hooks law

eps = strainTensor.rand(cs);

sigma = C_iso_Voigt : epssigma = stressTensor (y↑→x)

rank: 2 (3 x 3)

77.13 19.11 31.25

19.11 75.83 39.35

31.25 39.35 65.83in terms of the Lame constants by

sigma = stressTensor(2 * mu * eps + lambda * trace(eps) * tensor.eye)sigma = stressTensor (An0 Albite 2016)

type: Lagrange

rank: 2 (3 x 3)

77.13 19.11 31.25

19.11 75.83 39.35

31.25 39.35 65.83Hashin Shtrikman Bounds

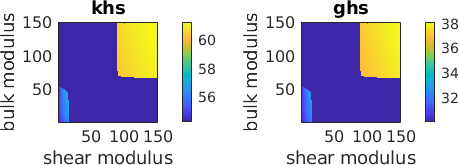

While the Voigt and Reuss bounds are tight without additional assumptions, the extreme cases require a very specific layered microstructure. If one additionally assumes that the material is quasihomogeneous, i.e., it is constant elastic properties within each subregion that is significantly larger then the grain size, then the Voigt and Reuss bounds are to wide. More narrow bounds for this settings have been established by Hashin and Shtrikman in 1962.

The following deviation follows the paper by J.M. Brown (2015) Determination of Hashin-Shtrikman bounds on the isotropic effective elastic moduli of polycrystals of any symmetry, Computers & Geosciences, 80 (2015) 95-99.

The upper and lower Hashin-Shtrikman bounds for the bulk and shear moduli are found as a solution of an optimization problem. Lets first set up the search domain

% define a 2 dimensional domain of bulk and shear moduli

KMin = 1; KMax = 150; % minimum and maximum bulk moduli

GMin = 1; GMax = 150; % minimum and maximum shear moduli

Ko = linspace(KMin,KMax,300);

Go = linspace(GMin,GMax,300);

[G0Mesh,K0Mesh] = meshgrid(Go,Ko);Next the initial stiffness tensor is updated such that the residual stiffness tensor R remains either positive or negative definite.

[khs, ghs, def] = HashinShtrikmanModulus(C,K0Mesh,G0Mesh);

subplot(1,2,1)

imagesc(Go,Ko,khs)

set(gca,'YDir','normal')

title('khs')

xlabel('shear modulus')

ylabel('bulk modulus')

colorbar%('location','southoutside')

axis equal tight

subplot(1,2,2)

imagesc(Go,Ko,ghs)

set(gca,'YDir','normal')

xlabel('shear modulus')

ylabel('bulk modulus')

title('ghs')

colorbar%('location','southoutside')

axis equal tight

%subplot(1,3,3)

%imagesc(G0,K0,minmax)

%set(gca,'YDir','normal')

%title('minmax')

%colorbar('location','southoutside')

%xlabel('shear modulus')

%ylabel('bulk modulus')

%axis equal tightWarning: Tensor is not positive definite

Warning: Tensor is not positive definite

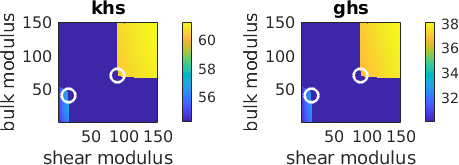

lower and upper Hashin Shtrikman bulk and shear modulus bounds

We find the lower Hashin Shtrikman bound of the bulk modulus by minimizing the effective Hashin Shtrikman bulk modulus over the positive definite domains of the residual stiffness tensor R. Accordingly we find the upper bound as the maximum over the negative definite domain.

khsLower = max(khs(def==1));

khsUpper = min(khs(def==-1));

ghsLower = max(ghs(def==1));

ghsUpper = min(ghs(def==-1));Lower and upper bounds are marked in the plots below.

subplot(1,2,1)

hold on

[i,j] = find(khs == khsLower);

plot(Go(j),Ko(i),'o','MarkerEdgeColor','w','linewidth',2)

[i,j] = find(khs == khsUpper);

plot(Go(j),Ko(i),'o','MarkerEdgeColor','w','linewidth',2)

hold off

subplot(1,2,2)

hold on

[i,j] = find(ghs == ghsLower);

plot(Go(j),Ko(i),'o','MarkerEdgeColor','w','linewidth',2)

[i,j] = find(ghs == ghsUpper);

plot(Go(j),Ko(i),'o','MarkerEdgeColor','w','linewidth',2)

hold off

Comparison of the bounds

Finally we compare the upper and lower Hashin Shtrikman bounds with the Voigt and Reuss bounds.

KReuss = C_iso_Reuss.bulkModulus;

KHill = C_iso_Hill.bulkModulus;

GVoigt = C_iso_Voigt.shearModulus;

GReuss = C_iso_Reuss.shearModulus;

GHill = C_iso_Hill.shearModulus;

disp(' ')

disp('bulk modulus')

cprintf([K,khsUpper,KHill,khsLower,KReuss],...

'-Lc',{'Voigt' '+HS' 'Hill' '-HS' 'Reus'})

disp(' ')

disp('shear modulus')

cprintf([GVoigt,ghsUpper,GHill,ghsLower,GReuss],...

'-Lc',{'Voigt' '+HS' 'Hill' '-HS' 'Reus'})

disp(' ')bulk modulus

Voigt +HS Hill -HS Reus

63.0889 60.326 58.5696 57.107 54.0503

shear modulus

Voigt +HS Hill -HS Reus

41.4333 36.7537 35.6344 32.8495 29.8355Note, that upper and lower bounds for all other elastic moduli can be computed from these upper and lower bounds of the bulk and shear modulus.