The sphericity as measure for grain boundary irregularity

Deformed polycrystalline materials such as ice often contain large grains interlocking with smaller grains, with many irregular grain boundaries. Boundary irregularity is hard to judge by visual inspection and it is better to use quantitative measures of boundary irregularity to infer processes across different deformation conditions. Here, we quantify the irregularity of each grain’s boundary by introducing a sphericity parameter \(\Psi\) which is calculated in 2-D from grain area A, grain boundary perimeter P, and area equivalent grain radius R by the formula

\[\Psi = \frac{A}{P \cdot R}\]

The grain sphericity \(\Psi\) is a useful indicator for grain boundary irregularity because it measures how closely a grain’s boundary resembles the circumference of a perfect circle. It decreases from \(\Psi = 0.5\), where the grain has a perfect circular shape, to \(\Psi = 0\) where the grain boundary is infinitely irregular. The statistics of grain boundary sphericity can be used to segregate recrystallised grains from remnant original grains (please refer to the paper for more details).

Data

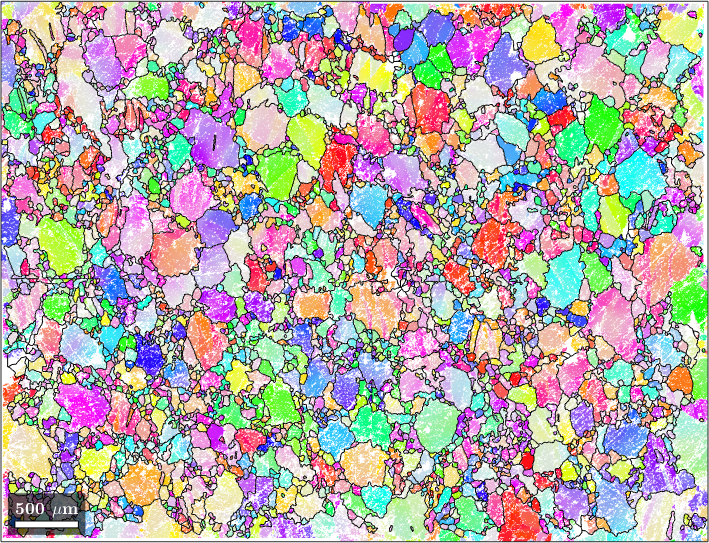

The EBSD data set used in this demonstration (PIL185.ctf) is available from https://doi.org/10.6084/m9.figshare.13456550. The EBSD data were collected with a step size of 5 µm and representeds an ice sample deformed at -20°C to 12 percent axial strain. Let's import the data and reconstruct some grains.

% plotting convention

plotx2east

plotzIntoPlane

% import the data

path = [mtexExamplePath filesep 'GrainExamples' filesep ];

ebsd = EBSD.load([path 'PIL185.ctf'],'convertSpatial2EulerReferenceFrame');

% critical misorientation for grain reconstruction

threshold = 10 *degree;

% first pass at reconstructing grains

[grains, ebsd.grainId] = calcGrains(ebsd('ice'),'angle',threshold);

% remove ebsd data that correspond to up to 4 pixel grains

ebsd(grains(grains.grainSize < 5)) = [];

% redo grain reconstruction - interpolate non-indexed space

[grains, ebsd.grainId] = calcGrains(ebsd('ice'),'angle',threshold);

% remove all boundary grains

grains(grains.isBoundary) = [];

% remove too small irregular grains

grains(grains.grainSize < grains.boundarySize / 2) = [];

% plot the result

plot(ebsd,ebsd.orientations)

hold on

plot(grains.boundary)

hold off

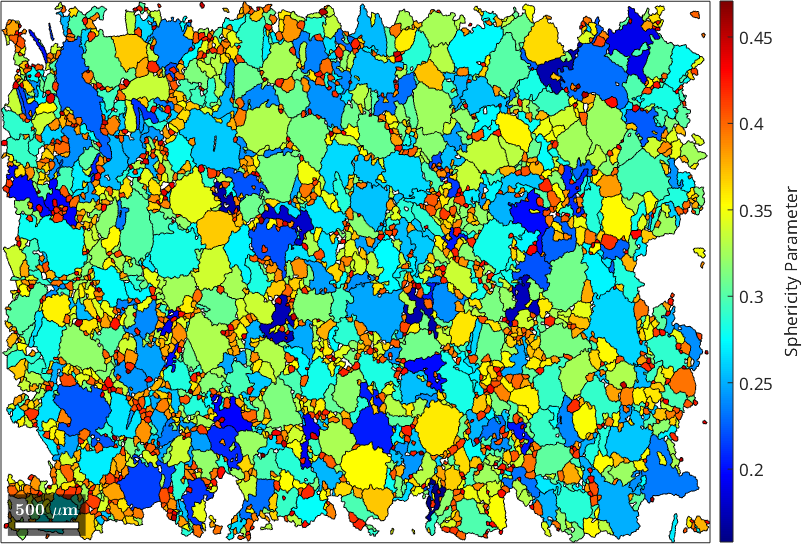

Computation of the Sphericity

Next, let's calculate and plot the sphericity parameter of each ice grain by making use of the functions grains.area, grains.perimeter and grains.equivalentRadius

% directly use the formula from the first paragraph

Psi = grains.area ./ grains.perimeter('withInclusion') ./ grains.equivalentRadius;

% plot the result

plot(grains, Psi, 'colorrange', [0 0.5])

mtexColorbar ('title','Sphericity Parameter')

mtexColorMap jet

clear Psi

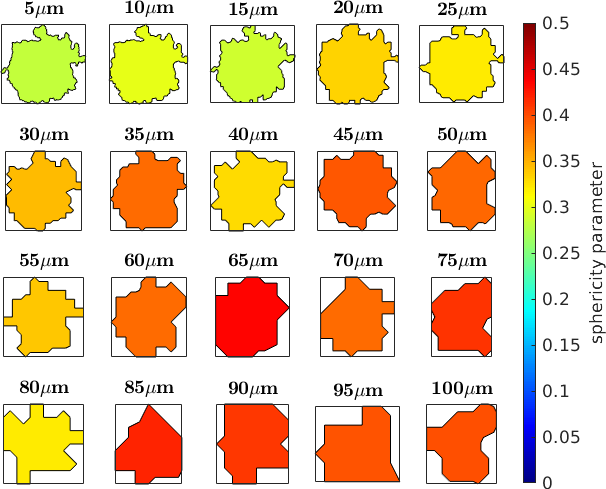

Influence of EBSD step size on sphericity parameter

Next we investigate how step size influences grain boundary irregularity measurements. To do this, we can artificially increase the step size of the EBSD data to from 10 up to 100 μm. Then, we choose one representative grain (one with a large number of pixels) and see how the sphericity parameter changes as the EBSD step size increases.

newMtexFigure('layout',[4,5])

for i = 1:20

% now, we increase the step size of EBSD data artifically

ebsd_reduced = reduce(ebsd,i);

% reconstruct grains using function calcGrains

grains_reduced = calcGrains(ebsd_reduced('ice'));

% choose a grain with a large pixel number within the EBSD map with 5

% micron step size, from each reduced EBSD map by location

grain = grains_reduced(findByLocation(grains_reduced('ice'), [1357 1952]));

% calculate the sphericity parameter

Psi(i) = grain.area ./ (grain.perimeter('withInclusion') .* grain.equivalentRadius);

% calculate the number of pixels

gS(i) = grain.grainSize;

% plot evolution of grain geometry as step size increases

if i>1, nextAxis; end

plot(grain, Psi(i),'doNotDraw','micronbar','off')

mtexTitle([int2str(5*i) '\(\mu\)m'],'doNotDraw');

end

setColorRange([0 0.5])

mtexColorMap jet

mtexColorbar ('title', 'sphericity parameter')

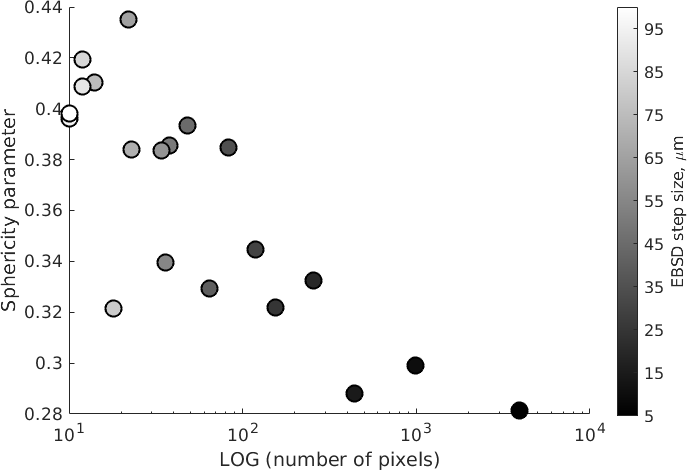

Now we are able to plot the sphericity parameter as a function of the step size.

clf

scatter (gS, Psi, 150,5:5:100,'filled','MarkerEdgeColor','k','linewidth', 1.5)

colormap gray

C = colorbar;

C.Label.String = 'EBSD step size, \mum';

C.Ticks = 5:10:100;

xlabel('LOG (number of pixels)')

ylabel('Sphericity parameter')

set (gca, 'xscale', 'log')

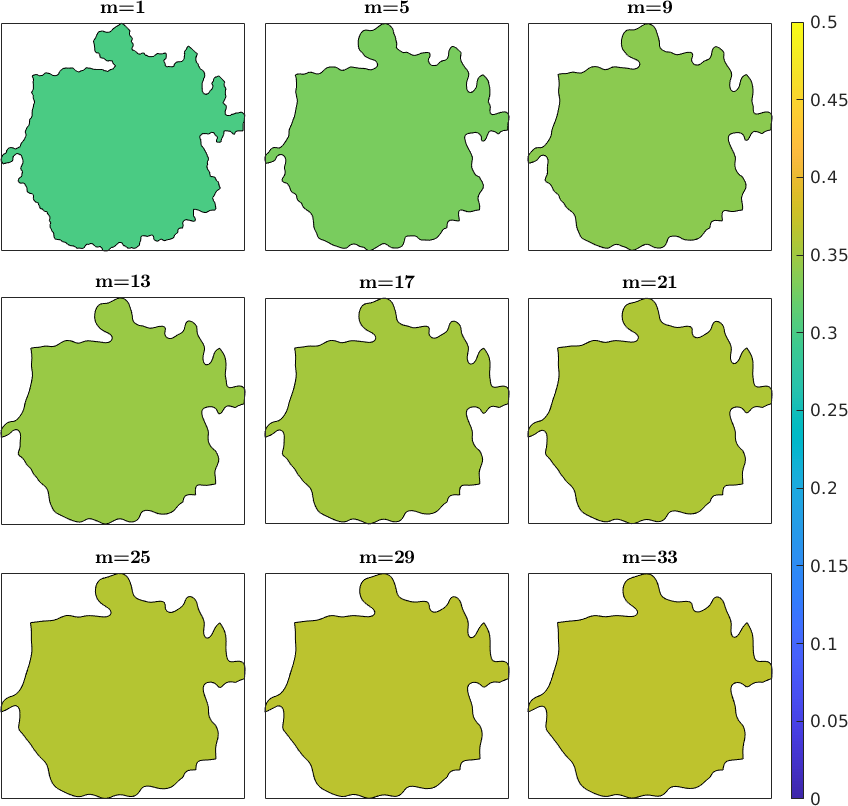

Influence of grain boundary smoothness on sphericity parameter

Due to the square shape of pixels (prescribed by Oxford Instruments software), boundary elements lie either vertically or horizontally within the plane of analysis. Grains containing fewer pixels (i.e., smaller grains in maps with a fixed step size) appear more pixelated than grains containing numerous pixels. MTEX allows us to reduce artificial pixelation of grain boundary elements by applying the function smooth, which enhances the overall grain boundary smoothness by interpolating the coordinates of grain boundary elements while triple junction points remain locked or unlocked. In this study, we choose to lock the triple junction during grain boundary smoothening.

newMtexFigure('layout',[3,3],'figSize','normal');

% find all grains with more than 2000 pixels

grains = grains(grains.grainSize > 2000);

for m = 1:36

% Smooth grain boundary to reduce pixelation, a larger m (smoothening

% parameter corresponds to a greater grain boundary smoothening

smoothGrains = smooth(grains, m);

% calculate the sphericity parameter for smoothed grains

Psi(m) = median(smoothGrains.area ./ smoothGrains.equivalentRadius ./ smoothGrains.perimeter('withInclusion') );

if mod(m,4)~=1, continue; end

% Visualise the evolution of grain boundary geometry as the smoothening

% parameter increases, using a grain as an example

% select grain

grain = smoothGrains(findByLocation(smoothGrains, [1357 1952]));

% plot it

if m>1, nextAxis; end

plot(grain, grain.area ./ grain.equivalentRadius ./ grain.perimeter('withInclusion'),...

'micronbar','off','doNotDraw');

mtexTitle(['m=',int2str(m)],'doNotDraw');

end

setColorRange([0 0.5])

mtexColorbar jet

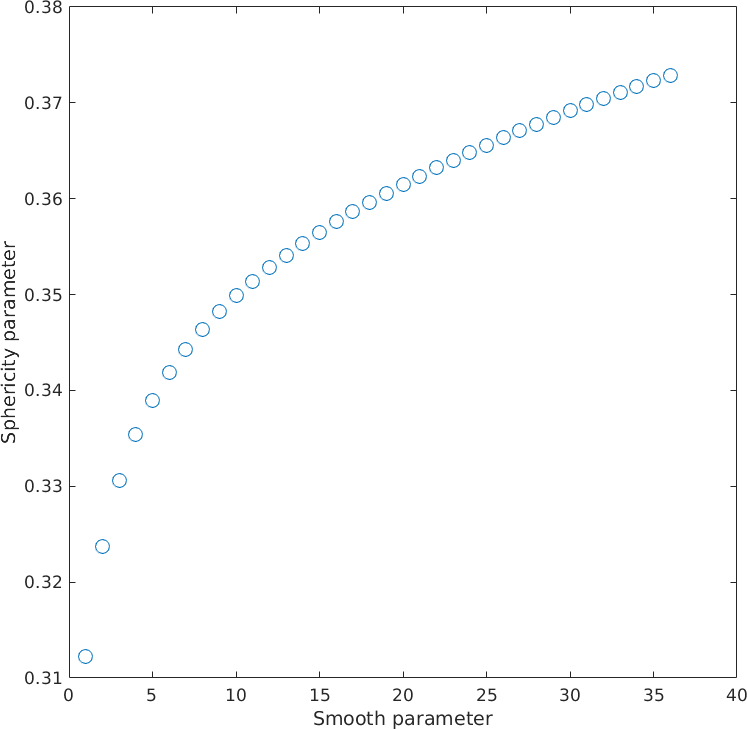

Finally we plot the sphericity as a function of the smoothening parameter

clf

plot(1:length(Psi), Psi, 'o')

xlabel ('Smooth parameter')

ylabel ('Sphericity parameter')

References

- Sheng Fan, David J. Prior, Andrew J. Cross, David L. Goldsby, Travis F. Hager, Marianne Negrini, Chao Qi, Using grain boundary irregularity to quantify dynamic recrystallization in ice, Acta Materialia, 2021.